Defective products are those which are dangerous or unfit for use. There are numerous cases of defective products in California. Hundreds of thousands or people annually, undergo medical and / or surgical treatment in emergency rooms as they were victims of defective products.

All those people who were affected by defective products can introduce a demand for compensation, as long as the defects of the product can be held responsible to someone in particular or some company, organization, and so on. In other words, victims of defective products are entitled to compensation if it is determined that the failure of the product was due to an error – whether intentional or not – in the process of manufacturing or designing the product. It is for this same reason that the demands that are made with class action character are valid and feasible.

There might also be legal liability if the victim was not properly notified about the risks associated with the product. It is important to emphasize the word “properly”, as many individuals and / or companies try to defend themselves by claiming that they warned about the consequences involved in the consumption of the product.

One of the advantages of introducing claims for defective products is that it is possible to demand compensation even if there are not visible injuries. Suppose, a child who sucked a toy coated with lead paint. While there is no “wound” visible, damage may occur later. And once the parents realize it, they will constantly monitor the child’s health status, without counting the stress and anxiety that they will suffer.

This type of lawsuits for future damages for defective products are generally introduced as class action, as in this way they can generate a greater impact in the court. In other words, a class action lawsuit gives greater visibility to the case and allows awareness of the seriousness of the matter.

The team of professionals at Avrek are the most suitable to handle such cases. Our lawyers are able to adequately advise any victim of defective products, whether for past, recent or future damages. Also, they know perfectly the correct procedure to file class action lawsuits.

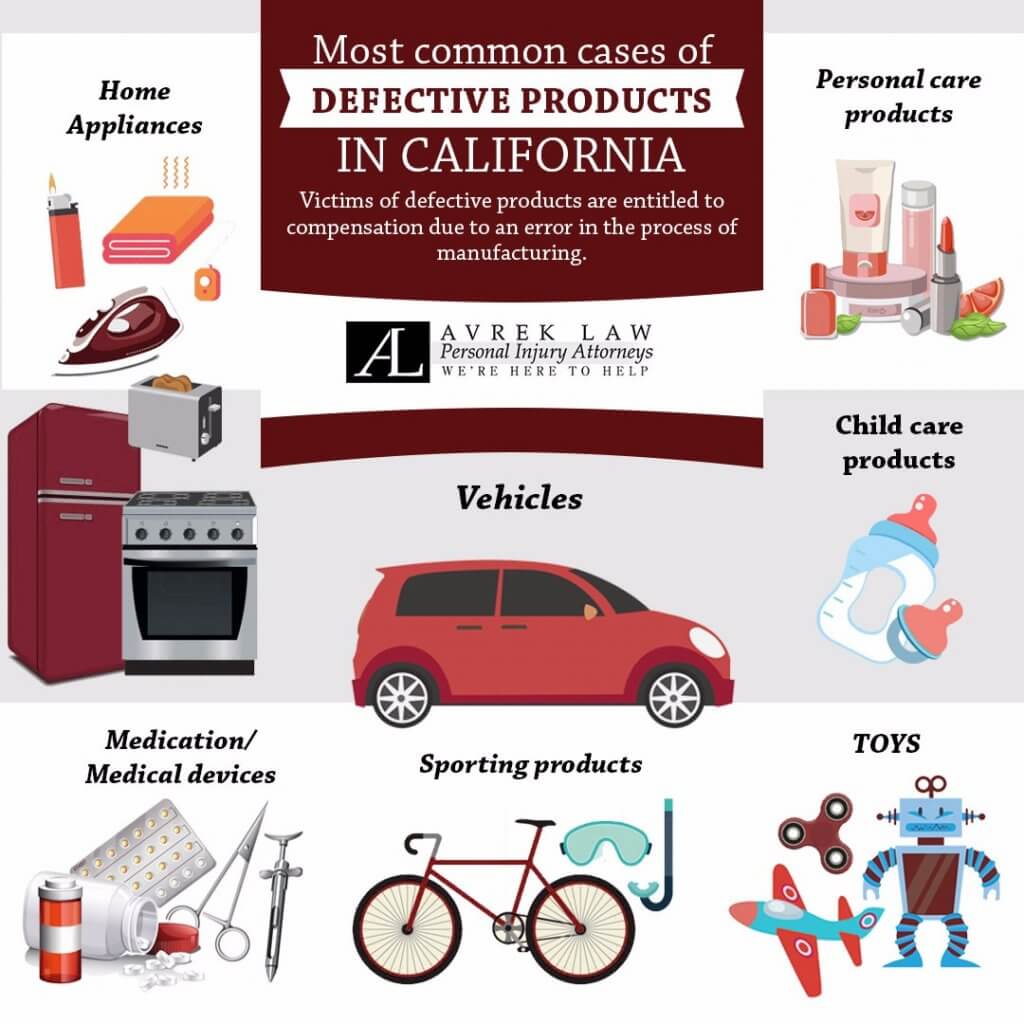

Following is information on the most common cases of defective products in California.

1. Vehicles

By law, all vehicles in California must undertake a regular inspection to ensure that they are safe to drive. This is pursuant to CFR, Title 49 §§391.11(b)(2) under the law of the state of California.

Error in vehicle manufacture is more frequent than most might think. Given the interrelation that exists between the components of a vehicle, such errors can trigger tragic results with fatal victims. Failures in vehicle safety mechanisms also fall into the category of defective products and can be the basis for claims, including class action ones.

The most common cases of vehicle manufacturing failures include the following: explosive airbags; ignition failures that reduce the power of the vehicle; faults in the cables that cause car incineration; failures in the steering mechanisms; defects in the latches that cause the hoods to open; transmission failures that abruptly affect vehicle speed; and – can’t miss – defects in the tires that cause accidents.

2. Personal care products

The Personal Care Products Safety Act 2015 was introduced in California to make sure that all personal products used by humans are safe. It also regulates the types of chemicals that are used so that they are in line with global health regulations.

The presence of chemicals harmful to health is a common denominator in personal care products. There are many cases in which it has been found that some personal care products may increase the risk of cancer incidence, precisely due to the presence of toxic chemical compounds.

The most common cases of defects in personal care products include the following: powders that increase the chances of getting ovarian cancer; perfumes, cosmetics, hair sprays and other personal care products that cause damage to the reproductive system; tampons that produce toxic shock syndrome; deodorants or antiperspirants that produce skin irritation or rashes; hair products that have a counterproductive effect; hair dyes that cause chemical burns and blisters.

3. Products for child care

According to statistics provided by the Consumer Product Safety Commission, defective child care products cause over 70,000 pediatric emergency admissions annually. as children’s bodies are in formation, they are more susceptible to being injured by defective products.

Child seats that fail to comply with safety regulations; cradles or pens in which children have the ability to put their heads on the rails; mattresses or bedding that can leak gases with high toxicity; teething rings, rattles, bottles, and so on., that have dimensions that can cause suffocation in infants or that have phthalates, a set of chemical compounds that can cause damage to the reproductive system.

4. Toys

U.S. toymakers follow a mandatory set of safety rules and regulations under ASTM F963 – Standard Consumer Safety Specification for Toy Safety. The rules regulate the types of plastic and methods used to make toys so that they are safe to be used by children. The rules have become globally used by other countries also.

The removal of toys from the shelves for safety reasons is a frequent phenomenon. Injuries that can be derived from defective toys include, the detachment of small parts that can be swallowed by children and cause suffocation; poisoning by contact with lead contained in the paint of the toys; and even dangerous eye injuries from sharp parts or irregular shapes.

The most common cases of toys with failures involve the following: scooters that do not have an adequate balance; dolls that can give off potentially suffocating tiny parts; toy cars whose wheels can be removed; plastic toys with high hardness that can break easily; plastic toys with low hardness that contain toxicity; dolls or action figures that contain lead in his painting; electronic toys that cause burns or blows; removable toys that release screws with pointed parts; tiny magnets that can cause internal damage; small motorcycles that do not have their signaling of risks.

5. Sporting products

Problems in the manufacture of sporting products are also common; It is incredible, but it is also dangerous to practice sports, precisely as it is possible to find tools with failures in their manufacture.

Weapons with failure in their safety levers, which causes them to shoot inadvertently; balance balls with risk of explosion if inflated too much; all-terrain vehicles with rollover hazard; ski bindings that are dismantled unexpectedly; trampolines lacking the necessary filler; snorkel masks that can break under water; bicycles or tricycles that do not comply with safety regulations.

6. Medicines

When a review of defective drugs claims is made, it can be noted that most of the claims have a class action character. In general, the victims of defective medications were so as the pharmaceutical company failed to warn about the risks related to the drug’s use.

Defective medications are usually the: anticoagulants whose use can cause internal bleeding; intestinal purification products that cause kidney failure; proton pump inhibitors that increase the risk of osteoporosis; antidepressants that induce suicidal behaviors; antibiotics that can cause ruptures in the tendons; oral intake contraceptives that increase the risk of strokes, heart and blood clots; diabetic medications that increase the chances of suffering from pancreatitis.

7. Medical devices

There are cases in which a doctor recommends his or her patient the use of medical devices and does not inform him about the inadvertent consequences of its use. Among them, the following: birth control coils that produce uncomfortable pains; valves for the heart with failures in its operation; hip and knee implants with low time-use that begin to fail and produce complications that result in additional operations; transvaginal mesh and pelvic sling devices that can cause bleeding and high-severity infections; bone filling material that can swell the neck and throat, causing respiratory complications.

8. Products for the home

The manufacturing defects can be located even in the products that we need for the day to day in our home. The defects can be caused by the use of materials of dubious quality; the use of wiring with defects; and even by poor designs.

Just to name a few: electric blankets with risk of overheating, so they can burn the skin; lighters that may explode inadvertently; batteries with a risk of overheating that can cause fires on a large scale; mattresses with risk of incineration; containers that lack the required ventilation for the fuel tank and other similar liquids; and herbicides and pesticides with levels of toxicity above the limit.

At the same time, we also find defects in construction materials and household appliances: refrigerators with a faulty ignition that can cause fires; stoves and microwaves whose handles have a high risk of overheating, so they can cause serious burns; floor materials presenting formaldehyde in its chemical composition; sprinkler systems and smoke detectors with failures in their function; gas water heaters that can cause fires; and kilns that give off carbon monoxide.

How much is your case worth?

Get a free case evaluation